Breve introducción:

Polyvinyl Alcohol 26-88 (also known as PVA 2688 or 088-60) is an ultra-high viscosity, partially hydrolyzed grade polymer.

With a viscosity of ≥ 60.0 mPa.s, PVA 26-88 offers the highest molecular weight and thickening capability in the 88-series. It is specifically engineered for critical industrial processes such as suspension polymerization of PVC and Polystyrene, where superior protective colloid properties are required to control particle size and porosity.

Presupuesto:

| Artículo | Especificación |

|---|---|

| Degree of Alcoholysis (mol%) | 98.00 - 100 |

| Viscosity (mPa·s) | 76.0 - 85.0 |

| Volatile Content (wt%, max) | 5 |

| Purity (wt%, min) | 93.5 |

| Valor de pH | 5 ~ 7 |

| Ash Content (wt%, max) | 0.5 |

Main Characteristics:

- Ultra-High Viscosity: Provides exceptional thickening power and solution stability even at low concentrations.

- Solubilidad: Soluble in water. Requires dissolving in hot water (above 90°C) to ensure the high molecular weight chains are fully hydrated.

- Protective Colloid: Offers superior surface activity and interface protection, making it critical for suspension polymerization processes.

- Film Properties: Forms a tough, flexible film with excellent barrier properties against Hydrogen ($H_2$), Nitrogen ($N_2$), and Oxygen ($O_2$).

- Reactivity: Capable of cross-linking with boric acid or undergoing acetalization for improved water resistance.

Aplicaciones:

PVA 26-88 is chosen for applications requiring maximum viscosity and stabilization:

- Suspension Polymerization (PVC/PS): Used as a primary dispersing agent (suspension granulating agent) for producing Polyvinyl Chloride (PVC) y Polystyrene (PS) granules. It controls particle size distribution and porosity.

- PVAc Emulsions: Acts as a high-efficiency protective colloid for vinyl acetate polymerization, improving emulsion stability and viscosity.

- Thickeners: Used widely as a thickening agent in latex paints, paper coatings, and textile pastes due to its high molecular weight.

- Photosensitive Materials: Key component in manufacturing fluorescent photosensitive agents and screens.

- Re-wettable Adhesives: Provides the necessary body and tack for remoistening glues.

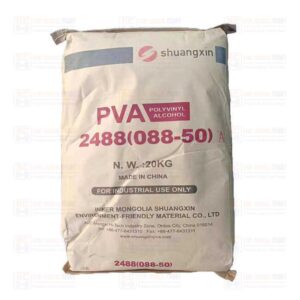

Embalaje:

- Embalaje: 25 kg per bag (Kraft paper bag with plastic liner).

Producto Almacenamiento:

- Almacenamiento: Store in a cool, dry, and well-ventilated area to prevent caking and moisture absorption.

FAQ:

Q: What is the difference between PVA 24-88 and PVA 26-88?

A: The main difference is viscosity and molecular weight.

-

PVA 24-88: Viscosity range is 43.0 – 65.0 mPa.s.

-

PVA 26-88: Viscosity is ≥ 60.0 mPa.s (typically higher). PVA 26-88 is used when you need the absolute maximum thickening effect or specific particle size control in PVC production that 24-88 cannot achieve.

Q: Why is PVA 26-88 used in PVC production?

A: In PVC suspension polymerization, PVA 26-88 acts as a dispersing agent. Its high degree of polymerization and partial hydrolysis help form a protective membrane around monomer droplets, preventing coalescence and ensuring uniform PVC resin particle size.

Q: Is PVA 26-88 soluble in cold water?

A: No, due to its very high molecular weight (indicated by high viscosity), it strongly requires hot water (90°C+) and sufficient agitation time to dissolve completely.

Looking for Ultra-High Viscosity PVA? Rearch out to us. We supply premium Polyvinyl Alcohol 26-88 for PVC manufacturing and industrial thickening.