Изучение поливинилового спирта (ПВС): ключевого игрока в текстильной, строительной и других отраслях

Поливиниловый спирт (ПВС) — водорастворимый, нетоксичный и биоразлагаемый полимер, получаемый путем полимеризации винилацетата с последующим алкоголизом. Свойства ПВС определяются степенью его полимеризации и алкоголиза, что делает его весьма универсальным. Он проявляет превосходные пленкообразующие, адгезионные и эмульгирующие свойства. ПВС широко используется в текстильной, строительной, клеевой, лакокрасочной и различных других отраслях промышленности благодаря своей стабильности, химической стойкости и биоразлагаемости.

Introduction to Polyvinyl Alcohol (PVA)

Имя

- Chemical Name: Polyvinyl Alcohol

- English Name: Polyvinyl Alcohol

- English Abbreviation: PVA

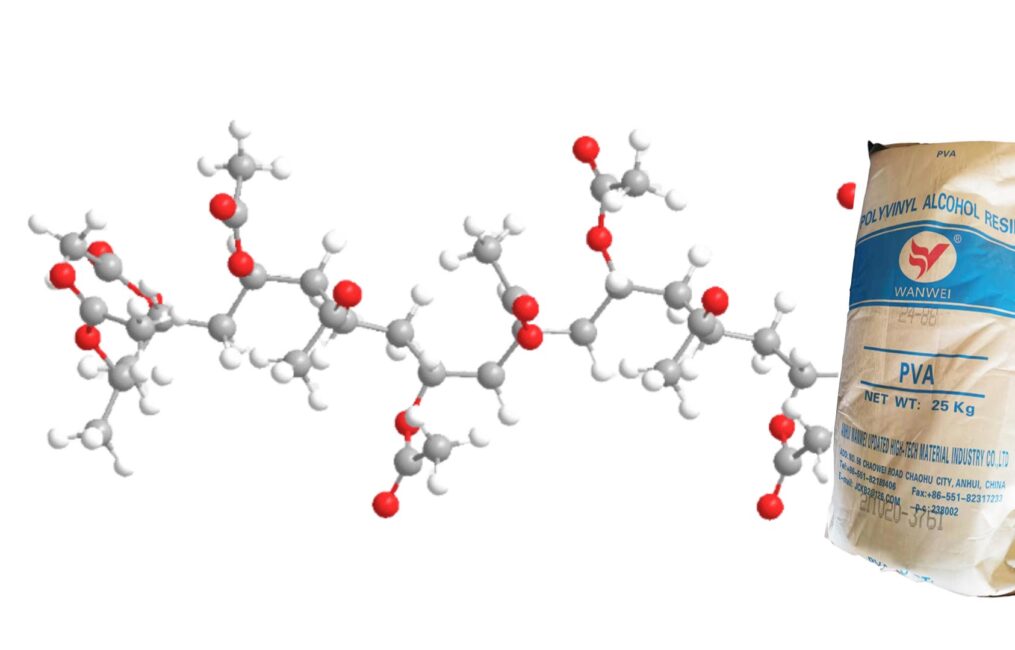

Molecular Composition and Structure

- Molecular Formula: (CH₃CHCOOCH₃)ₓ (CH₂CHOH)ᵧ

- Where:

- x+yx+y represents the degree of polymerization.

- yx+yx+y**y represents the degree of alcoholysis.

- Where:

Physical Properties

- Появление: White flake, granular, or powdery solid (low-alkali alcoholysis process) or white flocculent solid (high-alkali alcoholysis process).

- Density: 1.23–1.31 g/cm³.

- Flake PVA bulk density: 0.42–0.52 g/cm³.

- Flocculent PVA bulk density: 0.20–0.27 g/cm³.

Chemical Properties

- Structural Formula: -[CH₂CH(OH)]ₙ-, where nn represents the average degree of polymerization.

- The fundamental properties of PVA are determined by its average degree of polymerization and alcoholysis. However, the presence of more than 10 irregular structures in PVA molecules also significantly affects its performance.

- Water Solubility:

- PVA molecules contain a large number of hydroxyl groups, making them easily soluble in water.

- Solubility increases with water temperature.

- Swells in cold water (low-alcoholysis products can slowly dissolve in room-temperature water).

- Completely dissolves in hot water, forming a solution with excellent film-forming and adhesive properties.

- Thermal Stability:

- Softens when heated.

- No significant changes below 40°C.

- Prolonged heating above 160°C causes gradual discoloration.

- Decomposes above 220°C, producing water, acetic acid, acetaldehyde, and crotonaldehyde.

- Chemical Resistance:

- Almost unaffected by weak acids, weak bases, or organic solvents.

- High oil resistance.

- Storage Stability:

- Excellent stability; does not mold, deteriorate, or absorb moisture when stored in a naturally dry state.

- Reactivity:

- PVA is a polymer with secondary hydroxyl groups.

- The secondary hydroxyl groups in PVA molecules are highly reactive and can undergo typical chemical reactions similar to low-molecular-weight alcohols, such as esterification, etherification, and acetalization.

- Reacts with many inorganic and organic compounds.

- Non-toxic to humans and animals, biodegradable, and recognized as an environmentally friendly product.

Storage, Transportation, and Market Applications

- Production and Properties:

- Polyvinyl Alcohol (PVA) is produced by the polymerization of vinyl acetate followed by alcoholysis.

- It is a white, stable, non-toxic, water-soluble polymer that dissolves quickly in water to form a stable colloid. Water is an excellent solvent for PVA.

- Film-Forming and Emulsifying Properties:

- PVA aqueous solutions exhibit excellent film-forming and emulsifying properties.

- The formed films have exceptional adhesion, solvent resistance, friction resistance, tensile strength, and oxygen barrier properties.

- PVA contains both hydrophilic and hydrophobic functional groups, making it a surface-active substance. It can act as a protective colloid in emulsion and suspension polymerization reactions.

- Приложения:

- PVA is primarily used in the production of synthetic fibers, plastics, adhesives, coatings, and new building materials.

- Widely applied in industries such as chemicals, textiles, printing, papermaking, leather, and construction.

This overview highlights the key characteristics, properties, and applications of Polyvinyl Alcohol (PVA), emphasizing its versatility and eco-friendly nature.