Red Iron Oxide: Natural vs. Synthetic (A B2B Guide)

Red iron oxide can be natural or synthetic. Learn which offers the purity, consistency & performance needed for industrial coatings, concrete & plastics.

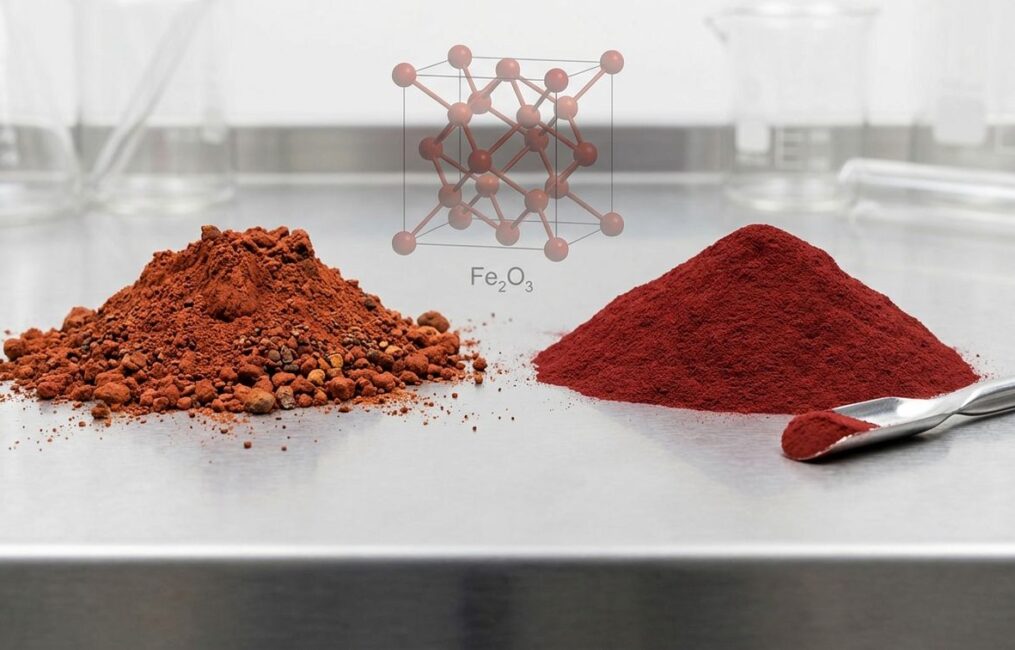

Is Red Iron Oxide Natural? A Direct Answer for Formulators

The question, “is red iron oxide natural?” has a nuanced answer critical for industrial applications: it can be both. Red iron oxide exists as a natural red ochre pigment mined from the earth and as a high-purity manufactured iron oxide red created through precise chemical synthesis. While both are based on the same chemical compound—iron(III) oxide (Fe₂O₃)—their origins, purity, and performance characteristics are vastly different. For procurement engineers and formulators in coatings, construction, and plastics, understanding these differences is key to ensuring product quality, consistency, and compliance.

This article provides a definitive comparison between natural and synthetic iron oxides, clarifying their production, properties, and ideal applications to guide your material selection process.

Understanding Natural Red Iron Oxide

Natural iron oxides are among the oldest pigments used by humanity, valued for their durability and earthy tones. Their origin is purely geological, shaped by millennia of natural processes.

The Role of Hematite Pigment and Natural Red Ochre

The primary mineral source for natural red iron oxide is hematite pigment (α-Fe₂O₃), one of the most abundant minerals on Earth’s surface. Deposits of hematite, mixed with varying amounts of clay, silica, and other minerals, are known as ochre. This natural red ochre is what is mined to produce natural earth pigments. The specific mineral composition of the deposit dictates the final shade, which can range from a dull, earthy red to a brighter, more vibrant hue. However, this natural origin is also the source of its primary industrial drawback: inherent inconsistency.

Mining and Processing Natural Earth Pigments

The production of natural red iron oxide is a mechanical, rather than chemical, process. It typically involves:

- Extraction: Mining the raw ochre or hematite ore from open-pit mines.

- Crushing and Grinding: Reducing the large ore chunks into a manageable size.

- Washing and Separation: Removing larger impurities like sand and rock through levigation (a process of washing and settling).

- Drying and Milling: The purified pigment slurry is dried and then finely milled to achieve a specific particle size suitable for use as a pigment.

This process refines the raw material but does not alter its fundamental chemical composition. Consequently, impurities remain, impacting color, tinting strength, and chemical properties.

Defining Synthetic Red Iron Oxide

In contrast to their natural counterparts, synthetic iron oxides are the workhorse of the modern pigment industry. They are produced under tightly controlled laboratory and plant conditions to achieve unparalleled purity and consistency.

Synthetic Red Iron Oxide Definition and Classification

A synthetic red iron oxide definition refers to an iron(III) oxide pigment (Fe₂O₃) produced through chemical synthesis rather than mining. It is classified under the Colour Index as C.I. Pigment Red 101. These pigments are engineered to precise specifications, with manufacturers offering various grades, such as Red 110 (yellower shade), Red 130 (medium shade), and Red 190 (bluer shade), each with a unique particle size and shape that dictates its color and performance.

Synthetic Fe₂O₃ Production Methods

The superior properties of synthetic iron oxides stem from their manufacturing processes, which build the pigment particle by particle. The two primary methods for synthetic Fe₂O₃ production are:

- Precipitation Process (e.g., Penniman/Laux Process): This is the most common method. It begins with an iron salt solution (often ferrous sulfate, a co-product of the steel industry). Scrap iron is added, and air is bubbled through the mixture to precipitate iron oxide nuclei. By carefully controlling temperature, pH, and oxidation rate, these seed crystals are grown into particles of a specific size and shape. The resulting pigment (often starting as yellow iron oxide, FeOOH) is then washed, dried, and calcined (heated at high temperatures) to convert it to the stable red α-Fe₂O₃ form. This method offers exceptional control over the final product.

- Thermal Decomposition: This method involves the direct thermal decomposition of iron compounds. For example, heating ferrous sulfate directly can produce red iron oxide. While effective, the precipitation method generally provides finer control over pigment characteristics.

Critical Differences: Natural vs. Synthetic Iron Oxide

For an industrial formulator, the choice between natural vs synthetic iron oxide hinges on three critical performance factors: purity, consistency, and safety.

Pigment Origin and Purity Analysis

The most significant difference lies in pigment origin and purity. Synthetic red iron oxides typically boast an Fe₂O₃ content exceeding 96%, with minimal impurities. Natural pigments, by contrast, have a much lower Fe₂O₃ content, often between 60% and 85%, with the remainder consisting of silica, alumina (clays), and other metal oxides. These impurities can affect chemical reactivity, dispersion, and weatherability in the final product.

Color Consistency and Tinting Strength

Because synthetic production controls particle size and distribution, it delivers exceptionally high color consistency from batch to batch. This is non-negotiable for applications like architectural coatings or colored concrete where uniformity is paramount. Furthermore, the uniform, fine particles of synthetic pigments provide significantly higher tinting strength—often 5 to 10 times greater than their natural counterparts. This means less pigment is required to achieve the desired color depth, leading to formulation efficiencies.

Heavy Metal Content and Safety

Synthetic iron oxides are manufactured from purified raw materials, resulting in extremely low and predictable levels of heavy metals. This makes them safe for a wide range of applications, including those with human contact. Natural pigments can contain variable and sometimes elevated levels of trace heavy metals depending on the geology of the mine site.

For construction applications, standards like ASTM C979 (Pigments for Integrally Colored Concrete) set limits on water-soluble substances to ensure pigments do not interfere with the concrete’s setting time and strength. High-purity synthetic iron oxides reliably meet these standards, whereas natural pigments may require rigorous testing on a per-batch basis.

Applications: When to Use Manufactured Iron Oxide Red

While natural pigments are suitable for artistic applications or where an “earthy” variation is desired, high-performance industrial sectors almost exclusively rely on manufactured iron oxide red for its reliability and superior properties.

- Coatings & Paints: The high tinting strength, clean masstone, UV resistance, and chemical inertness of synthetic reds make them ideal for automotive, industrial, and architectural coatings that require long-term durability and color fidelity.

- Construction: For coloring concrete, paving stones, bricks, and roofing tiles, the batch-to-batch color consistency of synthetic pigments is essential to avoid checkerboarding and ensure project uniformity. Their purity also guarantees no negative impact on concrete’s compressive strength.

- Plastics & Masterbatches: Synthetic iron oxides offer excellent heat stability (often exceeding 800°C) and dispersibility, which are critical for withstanding the high temperatures of polymer processing without color shifting or degrading.

Summary Table: Natural vs. Synthetic Specification Comparison

The table below provides a clear, at-a-glance comparison of the typical technical specifications for natural and synthetic red iron oxide pigments.

| Propriété | Natural Red Iron Oxide (Ochre/Hematite) | Synthetic Red Iron Oxide (e.g., Red 130) |

|---|---|---|

| Formule chimique | Fe₂O₃ + impurities (SiO₂, Al₂O₃, etc.) | Fe₂O₃ |

| Teneur en Fe₂O₃ (%) | 60 – 85% | > 96% |

| Force de teinture (%) | Low to Moderate (Variable) | High (95 – 105% vs. Standard) |

| Absorption d'huile (g/100 g) | Variable, often higher (25-45) | Controlled, typically lower (22-28) |

| valeur du pH | Variable (5-9) | Controlled (4-8) |

| Résistance à la chaleur | Variable, may shift color due to impurities | > 800°C |

| Lightfastness (Blue Wool Scale) | 8 (Excellent) | 8 (Excellent) |

| Color Consistency | Low (Batch-to-batch variation) | Very High (ΔE < 1.0) |

| Purity / Impurities | Contains significant levels of silica, clays | Trace elements controlled to ppm levels |

In conclusion, while red iron oxide is indeed natural in its mineral form, the synthetic version offers the purity, consistency, and performance required for modern, high-specification industrial products. For reliable, repeatable results, the choice is clear: synthetic iron oxide is the superior material for formulators.