Polyvinyl Alcohol (PVA) Safety & SDS | Industrial Supplier

Is Polyvinyl Alcohol Toxic? Understanding Biocompatibility Polyvinyl Alcohol (PVA), widely recognized by its CAS number 9002-89-5, is a water-soluble synthetic polymer used extensively across industries ranging from construction adhesives to pharmaceutical packaging. For procurement officers and R&D engineers sourcing chemical raw materials, understanding the toxicity profile of PVA is the first step in ensuring regulatory

Is Polyvinyl Alcohol Toxic? Understanding Biocompatibility

Polyvinyl Alcohol (PVA), widely recognized by its CAS number 9002-89-5, is a water-soluble synthetic polymer used extensively across industries ranging from construction adhesives to pharmaceutical packaging. For procurement officers and R&D engineers sourcing chemical raw materials, understanding the toxicity profile of PVA is the first step in ensuring regulatory compliance and worker safety.

Generally, PVA is classified as non-toxic and non-hazardous. It is distinct from its precursor, Polyvinyl Acetate, and is produced through hydrolysis. The degree of hydrolysis (partially hydrolyzed vs. fully hydrolyzed) influences its physical properties but generally does not alter its low-toxicity classification. In standard industrial applications—such as a binder in cement-based tile adhesives or a film-former in coatings—PVA poses minimal risk to human health when handled correctly.

Human Safety and FDA Approval Status

The safety profile of Polyvinyl Alcohol is well-documented. In terms of acute toxicity, the oral LD50 (lethal dose for 50% of the test population) in rats is typically greater than 5000 mg/kg, classifying it as practically non-toxic. It is not considered a carcinogen, mutagen, or reproductive toxin under standard GHS (Globally Harmonized System) classifications.

Due to its inert nature, PVA is approved by major regulatory bodies, including the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), for specific applications. It is frequently listed under 21 CFR 175.105 (Adhesives) and 21 CFR 177.1670 (Polyvinyl alcohol film) for use in food contact surfaces. This regulatory clearance assures manufacturers that high-purity grades of PVA sourced from reliable suppliers like rawchemicalmart.com are safe for consumer-facing products.

Biocompatibility in Medical Applications

Beyond industrial uses, PVA exhibits excellent biocompatibility, meaning it does not trigger significant immune responses or toxicity in living tissue. This property makes it a staple in the medical and pharmaceutical sectors. It is widely used in:

- Hydrogels: For wound dressings that require moisture retention.

- Tablet Coatings: To protect active pharmaceutical ingredients (APIs).

- Contact Lenses: Due to its high water content and optical clarity.

While industrial grades used in construction (e.g., as a thickener or additive in dry mix mortars) are not intended for medical use without further purification, the inherent chemical structure remains biocompatible.

Interpreting the PVA Safety Data Sheet (SDS/MSDS)

For logistics managers and safety officers, the Safety Data Sheet (SDS) is the definitive document for handling chemical shipments. When reviewing an SDS for Polyvinyl Alcohol, it is crucial to focus on the Hazard Identification and Physical Properties sections to manage storage and transportation risks effectively.

Hazard Identification and Classification

Under the GHS and OSHA Hazard Communication Standard (29 CFR 1910.1200), Polyvinyl Alcohol is typically classified as Non-Hazardous. However, the physical form of the product dictates certain safety considerations:

- Combustible Dust: Like many organic powders (including RDP and starch ethers), fine PVA dust can form explosive mixtures with air if suspended in high concentrations near an ignition source.

- Slip Hazard: When spilled and mixed with water, PVA becomes extremely slippery, posing a significant fall risk in warehouse environments.

Physical and Chemical Properties

Understanding the technical specifications is vital for both safety and application performance. Below are typical parameters found in a standard Certificate of Analysis (COA) or SDS for industrial-grade PVA:

| Propiedad | Typical Value / Description | Relevance |

|---|---|---|

| Apariencia | White to cream powder or granules | Visual inspection for purity. |

| pH (4% Solution) | 5.0 – 7.0 | Compatibility with other mix ingredients. |

| Punto de fusión | 180°C – 230°C (Depends on hydrolysis) | Processing temperature limits. |

| Solubilidad | Soluble in water (hot or cold depending on grade) | Critical for formulation (e.g., adhesives). |

| Volatile Content | < 5% | Storage stability indication. |

| Flash Point | > 93°C (Open Cup) | Fire safety classification. |

Sourcing Industrial Grade PVA?

As a leading global supplier, Raw Chemical Mart provides a comprehensive portfolio of Polyvinyl Alcohol (PVA) tailored for high-volume manufacturing, from textiles to advanced adhesives.

Safe Handling and Storage Precautions

While PVA is chemically stable, its hygroscopic nature (ability to absorb moisture) requires strict adherence to storage protocols to maintain product quality and prevent “caking” or blocking within the packaging.

Recommended Personal Protective Equipment (PPE)

Although PVA is not a skin irritant, industrial handling involves dust generation. Standard PPE recommendations include:

- Respiratory Protection: Use a NIOSH-approved N95 dust mask or respirator if ventilation is poor to prevent inhalation of fine particulates.

- Eye Protection: Safety goggles with side shields to prevent mechanical irritation from dust.

- Hand Protection: Standard industrial gloves (rubber or nitrile) are recommended to maintain hygiene, though dermal absorption is negligible.

Procurement & Safety Tip: “Always ensure that eye wash stations are accessible in areas where PVA powder is decanted or mixed. While the chemical is pH neutral, solid particulates can cause physical abrasion to the cornea.”

Storage Stability and Incompatibilities

PVA is chemically stable but reactive under specific conditions.

- Moisture Control: PVA must be stored in a cool, dry, and well-ventilated area. High humidity can cause the powder to clump, rendering it difficult to dissolve or feed into automated hoppers.

- Incompatibilities: Keep away from strong oxidizing agents (e.g., peroxides, nitrates) and strong acids. Reaction with these substances can degrade the polymer chain or generate heat.

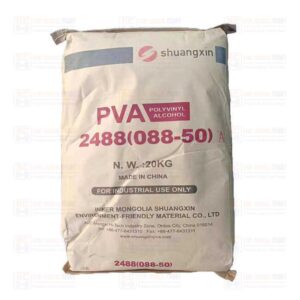

- Embalaje: At rawchemicalmart.com, we supply PVA in multi-layer paper bags with inner PE liners (typically 20kg or 25kg) to provide a robust moisture barrier during global transit.

Environmental Impact and Biodegradation

In today’s sustainable supply chain, the environmental footprint of raw materials is a key procurement criterion. Polyvinyl Alcohol is unique among synthetic polymers for its biodegradability.

How PVA Degrades in Wastewater Systems

Unlike many petrochemical plastics that persist for centuries, PVA is water-soluble and biodegradable under the right conditions. In wastewater treatment plants, specific microorganisms (such as Pseudomonas strains) can break down the PVA polymer chain. The process involves:

- Oxidation: The polymer backbone is oxidized by enzymes.

- Cleavage: The chain breaks into smaller carboxylic acids.

- Mineralization: Final degradation results in water and carbon dioxide.

However, facility managers should note that high concentrations of PVA can temporarily increase the Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD) in effluent water. Discharge rates should be monitored to ensure they remain within local environmental permit limits.

Ecological Impact on Aquatic Life

Ecotoxicological studies indicate that PVA has low toxicity to aquatic organisms. The LC50 (Lethal Concentration) for fish species typically exceeds 10,000 mg/L, suggesting that accidental spills into waterways, while undesirable, are unlikely to cause immediate mass mortality in aquatic ecosystems compared to other industrial solvents or biocides.

PVA Disposal Guidelines and Waste Management

Proper disposal of chemical waste is a legal and ethical imperative for industrial manufacturers. Because PVA is not classified as hazardous waste under the US RCRA (Resource Conservation and Recovery Act) or EU waste directives, disposal options are relatively flexible.

Regulatory Compliance for Industrial Disposal

When disposing of PVA waste (e.g., off-spec batches, spill cleanups, or empty packaging):

- Incineration: This is the preferred method for solid PVA waste. Since the polymer consists of carbon, hydrogen, and oxygen, complete combustion yields only carbon dioxide and water vapor, without generating toxic chlorinated byproducts (unlike PVC).

- Landfill: PVA can be disposed of in sanitary landfills in accordance with local regulations. Its slow biodegradation in anaerobic landfill conditions means it does not rapidly generate methane gas.

- Wastewater Discharge: Aqueous solutions containing PVA can often be discharged to biological treatment plants, provided the facility is capable of handling the associated BOD load. Always consult local water authority regulations before discharge.

Supply Chain Note: “For global shipments, rawchemicalmart.com ensures that all Polyvinyl Alcohol products are accompanied by up-to-date Safety Data Sheets (SDS) compliant with the destination country’s regulations, ensuring smooth customs clearance and safe handling upon arrival.”