Alcohol polivinílico (PVA): especificaciones, aplicaciones y perspectivas de la industria

El alcohol polivinílico (PVA) es un polímero sintético de alto rendimiento conocido por su excepcional capacidad de formación de película, solubilidad en agua y fuertes propiedades adhesivas. Ampliamente utilizado en diversas industrias, el PVA es un ingrediente clave en encolado textil, recubrimientos de papel, adhesivos y materiales de construcción. Sus especificaciones, incluyendo el grado de hidrólisis y la viscosidad, determinan su idoneidad para diferentes aplicaciones. El PVA totalmente hidrolizado ofrece una resistencia de película superior y resistencia química, mientras que los grados parcialmente hidrolizados ofrecen una mejor solubilidad. Desde la mejora de la durabilidad textil hasta la mejora de la adherencia de los adhesivos, el PVA desempeña un papel crucial en la fabricación moderna. Este artículo explora las especificaciones y las principales aplicaciones del PVA, ayudándole a elegir el grado adecuado para sus necesidades.

Polyvinyl Alcohol (PVA) is a versatile synthetic polymer known for its excellent film-forming, emulsifying, and adhesive properties. Due to its unique water solubility and chemical resistance, PVA is widely used in industries like textiles, paper manufacturing, construction, and adhesives.

WanWei PVA Specification(Non Fiber Grade)

Hydrolysis Degree (%): Determines the solubility of PVA in water. Higher hydrolysis levels (98-99%) result in limited water solubility, while partially hydrolyzed PVA dissolves more easily.

Viscosity (mPa.s): A key factor in determining the thickness and flow properties of PVA solutions, affecting applications in adhesives, coatings, and films.

| Artículo | Viscosidad (mPa.s) | Grado medio de polimerización | Grado de alcoholisis (Mol/mol) | Peso molecular | Volátil (%) | Humedad (%) | Ceniza (%) | pH |

|---|---|---|---|---|---|---|---|---|

| 04-88 (L) | 3.0-4.5 | / | 86.0-90.0 | / | 7.0 | 2.8 | 1.0 | 5-7 |

| 04-99 (L) | 3.0-4.5 | 300-450 | 98.0-100.0 | 13200-19800 | 7.0 | 2.8 | 1.0 | 5-7 |

| 05-88(L) | 4.0-6.0 | / | 86.0-90.0 | 17600-26400 | 7.0 | 2.8 | 1.0 | 5-7 |

| 05-99 (L) | 4.0-6.0 | 450-600 | 98.0-100.0 | 19800-26400 | 7.0 | 2.8 | 1.0 | 5-7 |

| 10-92 (L) | 8.0-10.0 | / | 90.0-94.0 | / | 7.0 | 2.8 | 1.0 | 5-7 |

| 10-99 (L) | 9.0-14.0 | 900-1100 | 98.0-100.0 | 39600-48400 | 7.0 | 2.8 | 1.0 | 5-7 |

| 14-92 (L) | 13.0-18.0 | / | 90.0-94.0 | / | 7.0 | 2.8 | 1.0 | 5-7 |

| 15-99 (L) | 20.0-26.0 | 1450-1650 | 98.0-100.0 | 63800-72600 | 7.0 | 2.8 | 1.0 | 5-7 |

| 17-80 (L) | 18.0-24.0 | / | 78.0-82.0 | / | 7.0 | 2.8 | 1.0 | 5-7 |

| 17-88 (L) | 20.0-28.0 | / | 86.0-90.0 | 72600-81400 | 7.0 | 2.8 | 1.0 | 5-7 |

| 17-92 (L) | 20.0-30.0 | / | 90.0-94.0 | 72600-81400 | 7.0 | 2.8 | 1.0 | 5-7 |

| 17-95 (L) | 20.0-30.0 | / | 94.0-96.0 | 72600-81400 | 7.0 | 2.8 | 1.0 | 5-7 |

| 17-96 (L) | 20.0-30.0 | / | 94.0-98.0 | / | 7.0 | 2.8 | 1.0 | 5-7 |

| 17-97(L) | 21.0-31.0 | 1650-1850 | 96.0-98.0 | 72600-81400 | 8.0 | 3.8 | 2.0 | 5-8 |

| 17-98 (L) | 20.0-30.0 | 1600-1800 | 97.0-99.0 | 70400-79200 | 7.0 | 2.8 | 1.0 | 5-7 |

| 17-99 (L) | 20.0-26.0 | 1680-1850 | 98.0-100.0 | 73900-82700 | 7.0 | 2.8 | 1.5 | 5-7 |

| 17-99 (H) | 20.0-26.0 | 1650-1850 | 98.5-100.0 | 72600-81400 | 9.0 | 7.0 | 3.0 | 5-7 |

| 19-99 (L) | 26.0-32.0 | 1800-2000 | 98.0-100.0 | 79200-88000 | 7.0 | 2.8 | 1.0 | 5-7 |

| 20-88 (L) | 28.0-40.0 | / | 86.0-90.0 | 81400-94600 | 7.0 | 2.8 | 3.0 | 5-7 |

| 20-99 (L) | 32.0-40.0 | 2000-2200 | 98.0-100.0 | 88000-96800 | 7.0 | 2.8 | 1.5 | 5-7 |

| 20-99 (H) | 34.0-42.0 | 2000-2300 | 98.5-100.0 | 88000-101200 | 9.0 | 7.0 | 1.0 | 5-7 |

| 22-99 (L) | 40.0-48.0 | 2200-2400 | 98.0-100.0 | 96800-105600 | 7.0 | 2.8 | 1.5 | 5-7 |

| 23-99 (H) | 42.0-55.0 | 2300-2600 | 98.5-100.0 | 101200-114400 | 9.0 | 7.0 | 3.0 | 5-7 |

| 24-88 (L) | 40.0-55.0 | / | 86.0-90.0 | 101200-110000 | 7.0 | 2.8 | 1.5 | 5-7 |

| 24-99 (L) | 48.0-60.0 | 2400-2600 | 98.0-100.0 | 105600-114400 | 7.0 | 2.8 | 1.5 | 5-7 |

| 26-99 (L) | 60.0-75.0 | 2600-2800 | 98.0-100.0 | 114400-123200 | 7.0 | 2.8 | 3.0 | 5-7 |

| 28-99 (L) | 75.0-90.0 | 2800-3000 | 98.0-100.0 | 123200-132000 | 7.0 | 2.8 | 1.5 | 5-7 |

Wanwei PVA Main Application

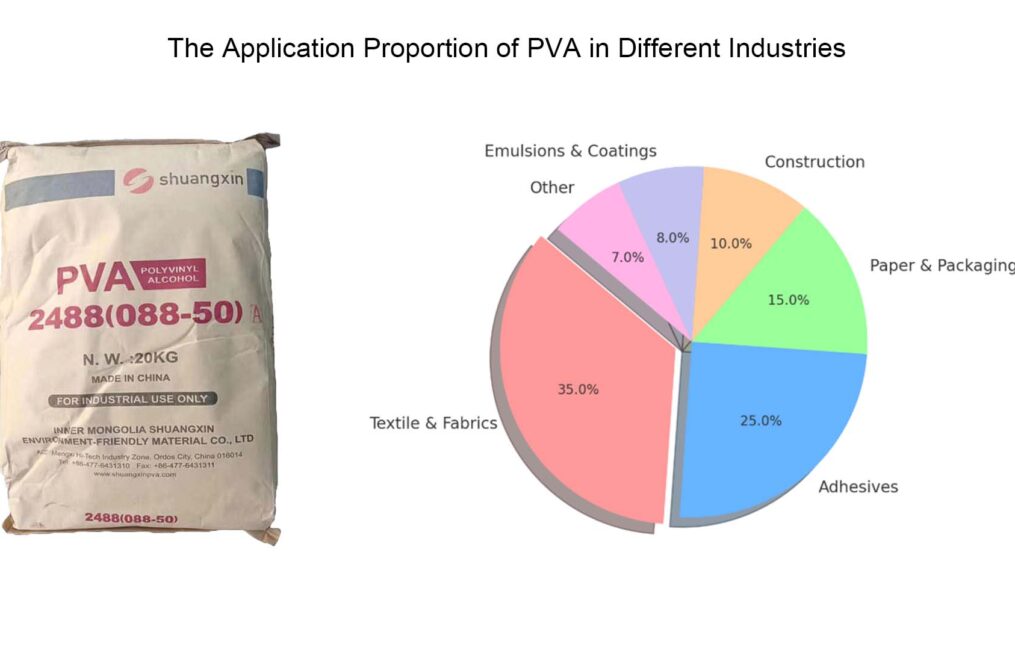

PVA is extensively used in textiles for fabric finishing and warp sizing, enhancing fiber strength during weaving. In adhesives, it serves as a key ingredient in wood glue and paper adhesives due to its strong bonding properties. Additionally, PVA plays a critical role in construction as a cement additive, improving workability and adhesion.

| Artículo | Solicitud |

|---|---|

| 04-88(L) 04-99(L) 05-88(L) | Medicine film, Outer pharmaceutical base materials, Water soluble film, High count,Flat printing photosensitive film, Paper making, Emulsion. |

| 05-99(L) 10-92(L) 14-92(L) | Medicine film, Outer pharmaceutical base material,Warp size, Emulsifier |

| 10-99(L) 17-80(L) | PVA dispersant in polymerization |

| 15-99(L) 17-88(L) 20-88(L) | Concrete modifier for oil well cemmenting, Soil improcement agent, Wet adhesive,Warp size,PVA film,PVAC Emulsion protective colloid, Light-sensitive Glue, PVB and so on. |

| 17-92(L) 17-96(L) 17-95(L) 17-98(L) 17-97(L) 19-99(L) 17-99(L) 20-99(H) 17-99(H) | Fabric sizing material, Fabric finishing agent, Paper surface sizing agent, Paper pigment binder, Paper adhesive, Emulsifier, PVA film, Thermoseting resin modifier, Ferrite bonded material, Dispersant, Coating, Clue, PVA, PVF and so on. |

| 17-99F(L) 17-99F(H) 26-99(L) | Vinylon, HSHM-PVA Fiber, Water soluble fiber, Flame reterdant hollow fiber and so on. |

| 26-99(L) | High viscosity adhesive, High-grade paint |

Looking for the right PVA grade for your application? Contact us today for expert recommendations and competitive pricing!