مقدمة موجزة:

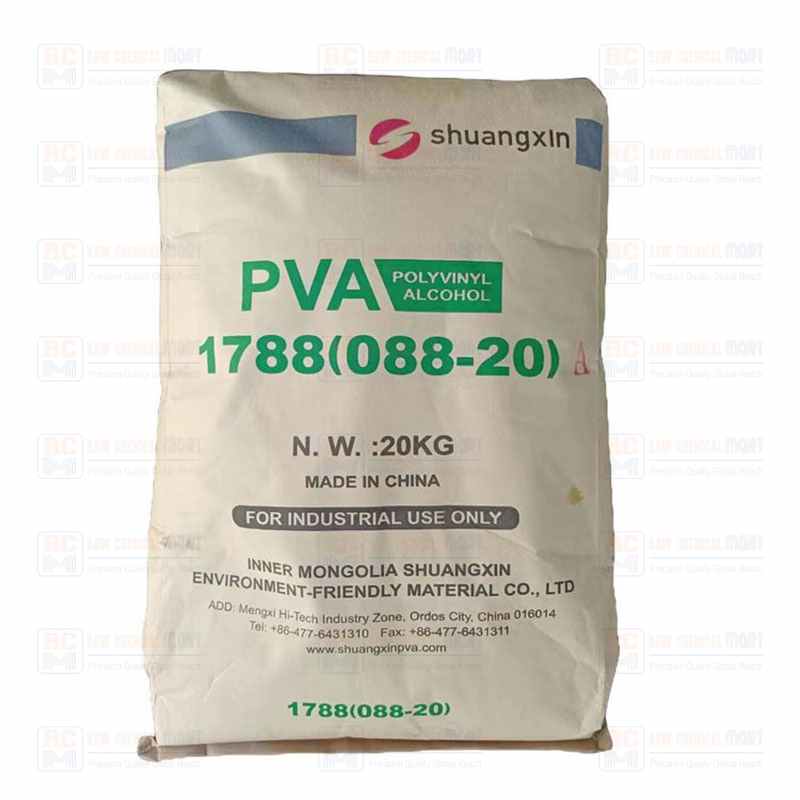

Polyvinyl Alcohol 1788 (also known as PVA 088-20) is a partially alcoholized, medium-viscosity grade water-soluble polymer. It is renowned for its excellent film-forming capabilities, strong adhesion, and superior emulsifying properties.

As a versatile raw material, our PVA 1788 is widely used across the construction, textile, and adhesive industries. It is soluble in water while remaining resistant to oils, grease, and most organic solvents, making it an essential additive for enhancing the performance of mortar, putty, and industrial adhesives.

تحديد:

| غرض | مواصفة | Test Method / Note |

|---|---|---|

| Product Name | Polyvinyl Alcohol (PVA) 17-88 / 1788 | |

| مظهر | White Powder / Particle | |

| Degree of Alcoholysis | 86.00 - 90.00 mol% | (Partially Hydrolyzed) |

| اللزوجة | 19.5 - 32.0 mPa.s | (4% aqueous solution at 20°C) |

| المحتوى المتطاير | ≤ 5.0 wt% | |

| نقاء | ≥ 93.5 wt% | (Calculated value) |

| قيمة الرقم الهيدروجيني | 5 ~ 7 | |

| Ash Content | ≤ 0.5 wt% |

التطبيقات:

Our PVA 1788 is engineered for diverse industrial applications:

-

Adhesive Industry: Acts as a primary binder for paper, wood, and textile adhesives. Its strong bonding strength makes it ideal for office glues and packaging adhesives.

-

Building Materials: Used as an additive in dry-mix mortars, putties, and tile adhesives. It improves water retention, flexibility, and bond strength of the cementitious material.

-

Paper Processing: Enhances the surface strength, printability, and oil resistance of paper products.

-

Film Processing: Due to its excellent film-forming properties, it is used to manufacture water-soluble films and protective coatings.

-

Stabilizer Industry: Functions as an effective emulsifier and protective colloid in the polymerization of vinyl acetate (PVAc) emulsions.

-

Plastic Molding: Used as a release agent and surface modifier in plastic production.

التعبئة والتغليف:

25 kg per bag.

منتج تخزين:

Store in a cool, dry, and well-ventilated area. Keep away from moisture and direct sunlight to maintain product quality.

FAQ:

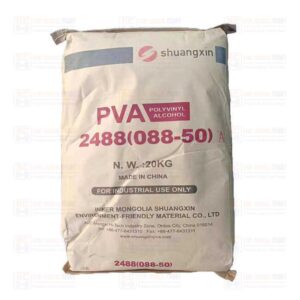

Q: What is the difference between PVA 1788 and PVA 2488?

A: The main difference lies in the viscosity و degree of polymerization. PVA 1788 typically has a lower viscosity (19.5-32.0 mPa.s) compared to PVA 2488, making 1788 more suitable for applications requiring faster dissolution and lower solution thickness. Both are partially hydrolyzed grades.

Q: Is PVA 1788 soluble in cold water?

A: PVA 1788 is a partially hydrolyzed grade (86-90%), which generally offers better water solubility than fully hydrolyzed grades. It can dissolve in warm water, but for complete dissolution and optimal performance, heating to specific temperatures (typically around 80-90°C) is recommended depending on the specific application process.

Q: Can PVA 1788 be used in food packaging adhesives?

A: Yes, due to its non-toxic nature and excellent adhesive properties, PVA 1788 is often used in adhesives for paper packaging that may indirectly contact food products.