الكربون الأسود المستخدم في المطاط: الخصائص والدرجات والتطبيقات

أسود الكربون مادة حشو أساسية مُقوِّية تُستخدم على نطاق واسع في صناعة المطاط، وخاصةً في الإطارات ومنتجات المطاط الصناعي. يُنتَج أسود الكربون عن طريق الاحتراق الجزئي للهيدروكربونات، ويتكون أساسًا من الكربون العنصري على شكل جسيمات دقيقة. تؤثر خصائصه - مثل حجم الجسيمات وبنيتها ونشاطها السطحي - بشكل مباشر على القوة الميكانيكية ومقاومة التآكل ومتانة مركبات المطاط.

الكربون الأسود is an essential ingredient in rubber compounding, widely used in tires, hoses, seals, conveyor belts, and countless industrial rubber products. It not only enhances mechanical performance but also affects the processing behavior, surface appearance, and aging resistance of rubber materials. In this article, we will explore how carbon black is produced, its characteristics in rubber applications, and a detailed comparison of key carbon black grades like N110, N220, N330, N550, N660, and others.

1. What Is Carbon Black and How Is It Made?

الكربون الأسود is a fine, powdery material composed predominantly of elemental carbon (>95%). It is produced by the incomplete combustion or thermal decomposition of hydrocarbons (such as oil or natural gas) under controlled conditions.

The most common production methods include:

- 🔥 Furnace Black Process: Used for most rubber blacks; hydrocarbons are burned in a limited oxygen environment to form fine carbon particles.

- 🌬 Channel Black & Acetylene Black: Used in specialty applications (not commonly for rubber).

The resulting carbon black consists of aggregates of primary particles, with surface area and structure that influence its reinforcing behavior in rubber.

2. Features of Carbon Black in Rubber Applications

Carbon black plays a multi-functional role in rubber formulations. Its performance depends heavily on particle size, structure, and surface activity.

Key Features:

| ملكية | Function in Rubber |

|---|---|

| Reinforcement | Increases tensile strength, modulus, and wear |

| Abrasion Resistance | Improves resistance to tread wear and erosion |

| UV Protection | Shields rubber from sunlight and ozone degradation |

| لون | Provides a black color and consistent appearance |

| Electrical Conductivity | Enhances conductivity in specialized applications |

| Heat Build-Up Management | Affects rolling resistance and energy dissipation |

The grade of carbon black directly affects rubber hardness, elasticity, and durability. Finer particles give stronger reinforcement but may reduce processability, while coarser grades offer better dispersion and flexibility.

3. Comparison of Common Carbon Black Grades for Rubber

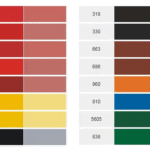

The ASTM N-series classification identifies carbon black grades used in rubber compounding. Below is a comparison of popular types, focusing on particle size, structure, and applications.

🔍 Carbon Black Specifications Comparison Table

| درجة | Surface Area (NSA, m²/g) | Particle Size (nm) | Structure (DBP, mL/100g) | Abrasion Resistance | Common Applications |

|---|---|---|---|---|---|

| ن110 | 145 ± 10 | ~20 | 113 ± 5 | Very High | High-performance tires, industrial rubber |

| ن220 | 120 ± 10 | ~25 | 114 ± 5 | High | Truck tires, conveyor belts, rubber rollers |

| ن330 | 77 ± 9 | ~26-30 | 102 ± 5 | Medium-High | Passenger tire treads, general rubber products |

| ن550 | 43 ± 5 | ~55 | 121 ± 5 | Medium | Tire sidewalls, flexible rubber compounds |

| ن660 | 35 ± 5 | ~60-70 | 95 ± 5 | Low | Inner tubes, soft rubber goods, seals |

| N772 | 25 ± 3 | ~75-90 | 65 ± 5 | Very Low | Weatherstrips, ozone-resistant parts |

ملحوظة: Surface area and structure values vary slightly by manufacturer. These are typical reference ranges.

4. Choosing the Right Grade

When selecting a carbon black for rubber compounding, consider:

- Reinforcement level required

- Abrasion and wear resistance

- Flexibility vs. stiffness

- Processability

- Cost-performance balance

على سبيل المثال:

- ✔ N110 / N220: For high-performance, highly loaded compounds

- ✔ ن330: All-purpose, balances reinforcement and processability

- ✔ N550 / N660: For flexibility, smooth extrusion, and soft products

خاتمة

Carbon black is a cornerstone additive in rubber formulations. Each grade brings unique structural and performance characteristics, influencing how rubber behaves under stress, aging, or environmental exposure. Understanding these differences allows formulators to design rubber compounds that are stronger, longer-lasting, and better suited to specific applications.

If you’re sourcing rubber-grade carbon black or looking for technical guidance, feel free to contact us for product data sheets, pricing, or application support.