Industrial Grade PVA Supply: Emulsion Formulation Guide

Understanding Polyvinyl Alcohol Dispersions In the competitive landscape of industrial chemical manufacturing, the formulation of stable emulsions is a critical competency for producers of adhesives, paints, and coatings. Polyvinyl Alcohol (PVA) serves as a cornerstone in this process, acting not merely as an additive, but as a fundamental structural component that dictates the rheology, stability,

Understanding Polyvinyl Alcohol Dispersions

In the competitive landscape of industrial chemical manufacturing, the formulation of stable emulsions is a critical competency for producers of adhesives, paints, and coatings. Polyvinyl Alcohol (PVA) serves as a cornerstone in this process, acting not merely as an additive, but as a fundamental structural component that dictates the rheology, stability, and film-forming properties of the final product.

At rawchemicalmart.com, we understand that for R&D engineers and procurement officers, the consistency of the raw material is just as vital as the chemistry itself. A PVA dispersion is essentially a colloidal system where the polymer acts as the interface between water and the monomer (typically vinyl acetate). Understanding the solubility profile and the molecular weight distribution of the PVA grade is the first step in engineering a high-performance emulsion that can withstand the rigors of global supply chains and varied application environments.

The Role of PVA in Emulsion Polymerization

Emulsion polymerization is a complex thermodynamic process where PVA plays a dual role. While surfactants lower surface tension, PVA provides the mechanical robustness required for the polymer particles to remain dispersed over time.

Function as a Protective Colloid and Stabilizer

PVA is widely recognized as the premier protective colloid for the polymerization of Vinyl Acetate Monomer (VAM). Unlike simple surfactants that can easily desorb from the particle surface, PVA chains absorb irreversibly onto the polymer particles. This creates a hydrated shell around the latex particles.

During the polymerization process, the “grafting” of vinyl acetate onto the PVA backbone occurs. This grafting efficiency is crucial; it determines the viscosity stability and the mechanical strength of the dried film. High-quality PVA from rawchemicalmart.com ensures a consistent degree of polymerization, allowing formulators to predict the grafting density accurately and avoid batch-to-batch variations.

Mechanisms of Steric Stabilization

Stability in emulsions is generally achieved through electrostatic or steric repulsion. PVA functions primarily through steric stabilization. The long polymer chains of PVA extend into the aqueous phase, creating a physical barrier that prevents the latex particles from coalescing.

Procurement & Handling Tip: Unlike electrostatically stabilized systems, steric stabilization provided by PVA is less sensitive to the presence of electrolytes or changes in pH. This makes PVA-stabilized emulsions robust choices for formulations that include ionic additives or pigments like Iron Oxide or Titanium Dioxide.

The effectiveness of this steric barrier depends heavily on the hydrolysis degree of the PVA. The residual acetate groups in partially hydrolyzed PVA act as “anchors” into the hydrophobic polymer particle, while the hydroxyl groups extend into the water, maintaining the dispersion.

Sourcing Industrial Grade PVA?

As a leading global supplier, Raw Chemical Mart provides a comprehensive portfolio of Polyvinyl Alcohol (PVA) tailored for high-volume manufacturing, from textiles to advanced adhesives.

Step-by-Step PVA Emulsion Formulation

Successful formulation requires precise control over raw material selection and processing conditions. Below is a technical guide to optimizing these parameters.

Selecting the Right PVA Grade (Hydrolysis & Viscosity)

The selection of the PVA grade is the most critical variable. The two primary parameters are the degree of hydrolysis (DH) and viscosity (molecular weight).

| PVA Grade Category | Hydrolysis Degree (DH) | Viscosity Range (mPa.s) | Impact on Emulsion Formulation |

|---|---|---|---|

| Partially Hydrolyzed | 87.0% – 89.0% | Low to Medium (e.g., 5-25) | Best for Emulsification. The hydrophobic acetate groups lower surface tension effectively, acting as a co-surfactant. Provides excellent freeze-thaw stability. |

| Fully Hydrolyzed | 98.0% – 99.0% | Medium to High (e.g., 20-60) | High Water Resistance. Used when the final film requires superior water resistance. Less effective as a primary stabilizer; often blended with partially hydrolyzed grades. |

| Modified Grades | Custom | Variable | Specialized for unique substrates or extreme viscosity requirements. |

Temperature and Mixing Protocols

Proper dissolution is non-negotiable for formulation success. Incomplete dissolution leads to “fish eyes” (undissolved gel particles) which ruin the texture of paints and weaken adhesive bonds.

- Dispersion: Slowly sift the PVA powder into cool water (20-30°C) under agitation. Rapid addition causes lumping.

- Heating: Once dispersed, raise the temperature.

- For Partially Hydrolyzed grades: Heat to 85°C–90°C.

- For Fully Hydrolyzed grades: Heat to 90°C–95°C.

- Dwell Time: Maintain temperature for 30–60 minutes under continuous stirring to ensure full molecular relaxation and solubility.

- Cooling: Cool slowly to prevent thermal shock before adding monomers or other additives.

PVA Applications in Paints and Coatings

Beyond adhesives, PVA emulsions are integral to the architectural coating industry. At rawchemicalmart.com, we supply raw materials that support the production of low-VOC, high-performance paints.

PVA as a Binder for Architectural Coatings

PVA emulsions (often PVAc) serve as the primary binder in interior latex paints. They offer excellent adhesion to porous substrates like drywall, wood, and plaster. The key advantage of using high-grade PVA is the balance between scrub resistance و cost-efficiency.

Furthermore, PVA contributes to the rheology of the paint, providing “body” and reducing dripping or splattering during application. For exterior applications, PVA is often copolymerized with softer monomers (like ethylene in VAE) to improve flexibility and weather resistance.

Optimizing Pigment Dispersion using PVA

In paint formulations, pigments such as Titanium Dioxide (Rutile or Anatase) need to be perfectly dispersed to achieve maximum opacity and whiteness. PVA aids in this process.

The polymer chains adsorb onto the pigment surfaces, preventing re-agglomeration. This compatibility is essential when formulating with our high-grade Titanium Dioxide or Iron Oxide pigments. A well-stabilized PVA system ensures that the color strength is developed fully and that the paint maintains a uniform hue over its shelf life.

Troubleshooting Stability and Viscosity Issues

Even with optimal formulations, issues can arise during scale-up. Here are common challenges and technical solutions:

- Phase Separation (Syneresis): Often caused by insufficient hydrolysis stability or bacterial attack. Solution: Ensure the PVA grade has the correct hydrolysis level (87-89% is usually most stable) and incorporate a biocide early in the process.

- Viscosity Drift: If viscosity increases uncontrollably over time, it may indicate continued grafting or instability. Solution: Check the pH. PVA is most stable in a slightly acidic to neutral range (pH 5-7). Strong alkalis can hydrolyze the residual acetate groups, changing the polymer’s properties in situ.

- Foaming: PVA is surface-active and prone to foaming. Solution: Use a compatible defoamer during the dissolution and polymerization stages. Mechanical agitation speed should be optimized to minimize air entrainment.

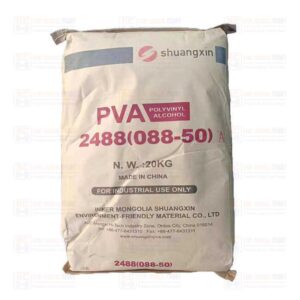

Safety & Logistics Note: While PVA is non-toxic and biodegradable, proper storage is vital. PVA is hygroscopic. rawchemicalmart.com ensures all PVA shipments are packaged in moisture-proof, multi-layer paper bags with inner PE liners to maintain flowability and specification integrity upon arrival.

Conclusion and Formulation Key Takeaways

Formulating with Polyvinyl Alcohol requires a deep understanding of polymer chemistry and strict adherence to processing parameters. Whether you are developing a high-tack wood adhesive or a premium interior emulsion paint, the choice of PVA grade dictates the stability and performance of your final product.

Key takeaways for B2B buyers and engineers include:

- Select by Hydrolysis: Use partially hydrolyzed grades (approx. 88%) for optimal emulsion stabilization.

- Control the Heat: Adhere strictly to dissolution temperatures to avoid gelation or incomplete solubilization.

- Leverage Steric Stabilization: Utilize PVA’s natural structure to create robust, electrolyte-resistant formulations.

At rawchemicalmart.com, we are more than just a supplier; we are your partner in the global supply chain. From premium PVA and RDP to essential pigments and water treatment chemicals, we provide the consistent quality and technical reliability necessary to keep your production lines running smoothly.