Polyvinyl Alcohol (PVA): The Multifunctional Material Powering Industries Worldwide

Polyvinyl Alcohol (PVA) is a versatile polymer with applications in various industries, including textiles, adhesives, paper, paints, food packaging, pharmaceuticals, and more. Its diverse applications stem from its key properties such as film-forming, adhesion, water solubility, chemical stability, non-toxicity, and biocompatibility. PVA’s properties can be fine-tuned by adjusting its degree of polymerization and alcoholysis to meet the specific needs of different applications.

Polyvinyl Alcohol (PVA): The Science Behind Its Diverse Applications

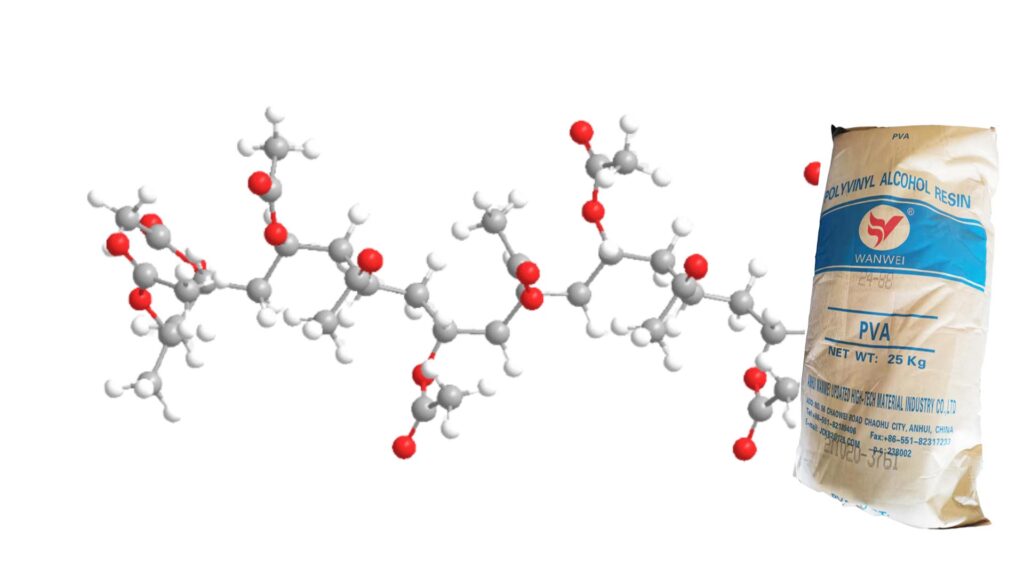

Polyvinyl Alcohol (PVA) is a versatile polymer with tunable properties based on its degree of polymerization (DP) and degree of alcoholysis (DH). High DP PVA results in high viscosity and strength, suitable for applications like textile sizing and high-strength adhesives. Low DP PVA offers low viscosity and fast dissolution, ideal for low-viscosity adhesives and cosmetics. Low DH PVA provides excellent water solubility, making it suitable for textile sizing and water-soluble films. High DH PVA exhibits excellent water resistance and chemical stability, used in food packaging and pharmaceuticals.

Exploring Polyvinyl Alcohol (PVA): A Key Player in Textiles, Construction, and Beyond

Polyvinyl alcohol (PVA) is a water-soluble, non-toxic, and biodegradable polymer produced through the polymerization of vinyl acetate followed by alcoholysis. PVA’s properties are determined by its degree of polymerization and alcoholysis, making it highly versatile. It exhibits excellent film-forming, adhesive, and emulsifying properties. PVA is widely used in textiles, construction, adhesives, coatings, and various other industries due to its stability, chemical resistance, and biodegradability.